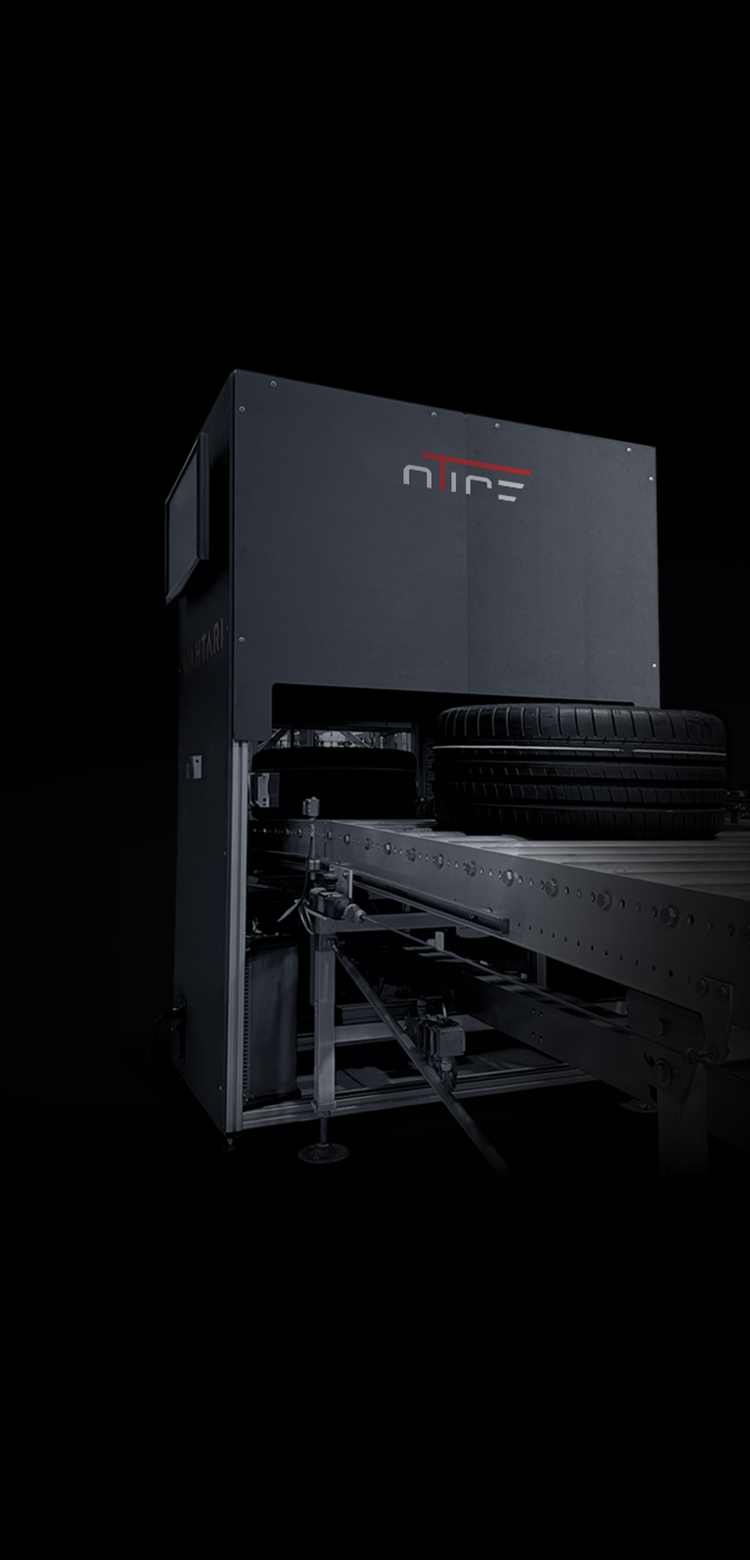

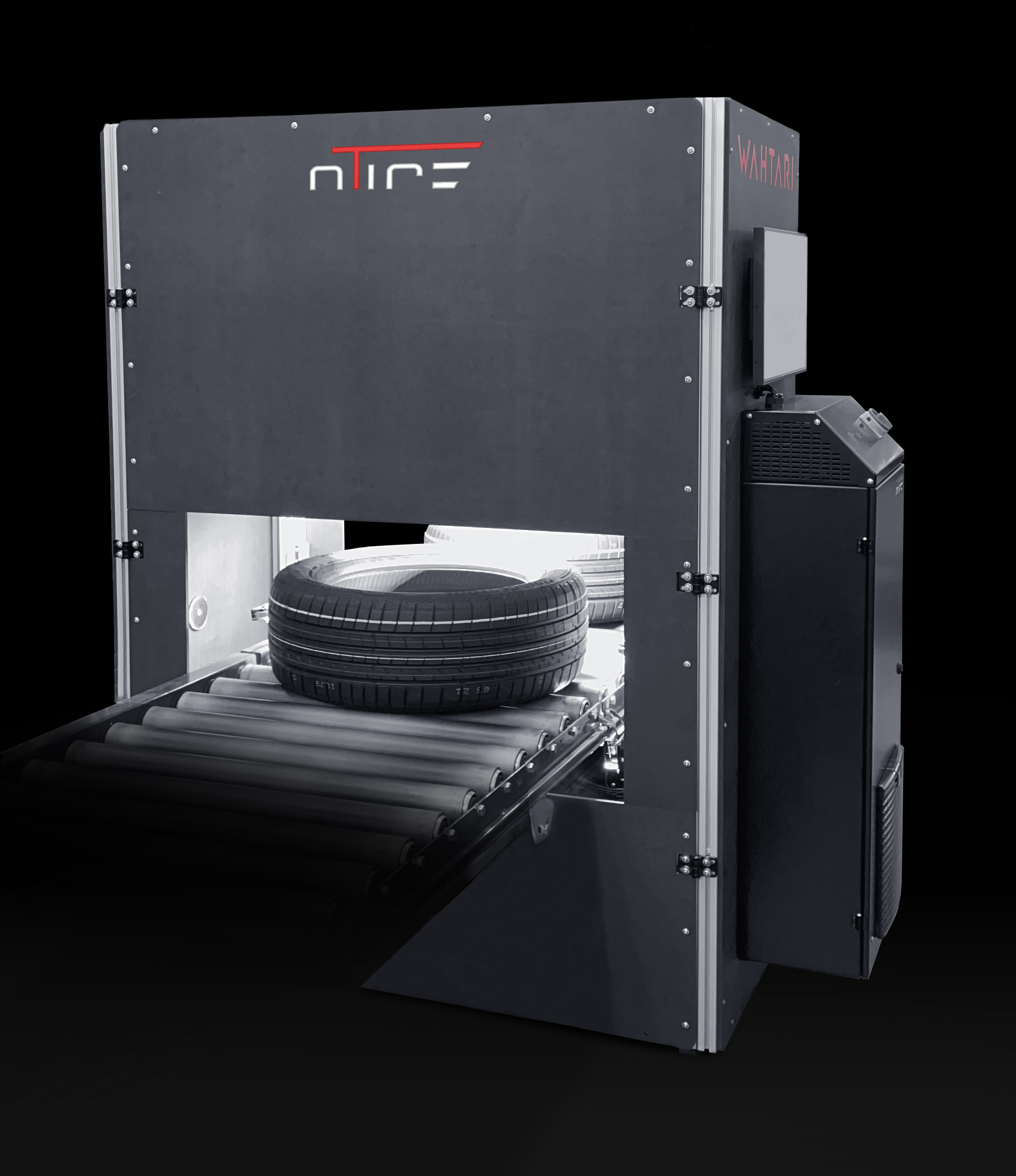

nTire – AI-Supported DOT Code Recognition

Fully automated DOT/TIN code recognition on tires and wheel assemblies

OCR Technology

AI-supported recognition of tire markings (DOT, TIN and DOM codes)

Inspection from Both Sides

Automatic tire identification on the roller conveyor, no turning necessary

Cycle Time | Speed

Per Tire: < 5s

Speed from: 0.3 m/s – 0.8 m/s

100% Coverage

Seamless inspection and secure DOT code traceability

Seamless Connectivity

PROFIBUS, PROFINET, OPC UA

Detection rate > 99.5%

Maximum precision and safety in production

Automated DOT/TIN Inspection in Real Time

The DOT number is crucial for traceability and quality control in tire production, but different embossing, low contrast, and variable code lengths make reliable detection difficult.

Wahtari's nTire inspection system offers a fully automated, optical solution – precise, fast, and reliable.

Using state-of-the-art deep neural networks, nTire recognizes tire identification numbers (DOT, TIN, and DOM codes) in real time, even on low-contrast surfaces.

The analysis is performed on-the-edge, completely without a cloud or internet connection.

This guarantees highest speed, maximum data security, and minimum latency.

Thanks to its modular design, nTire is versatile and can be seamlessly integrated into existing production processes.

Precise Code Detection Directly on the Tire Sidewall

Get in touch with us

Would you like to find out more about our inspection solution? Get in touch with us and one of our experts will get back to you as soon as possible: [email protected]

Intuitive User Interface

for Maximum Control

The nTire user interface provides a live view of the ongoing DOT code detection, enabling continuous monitoring of the inspection process.

A clear status display keeps you informed of the current system status at all times, while detected or defective DOT/TIN codes are signaled in real time – for maximum transparency and full control of your production line.